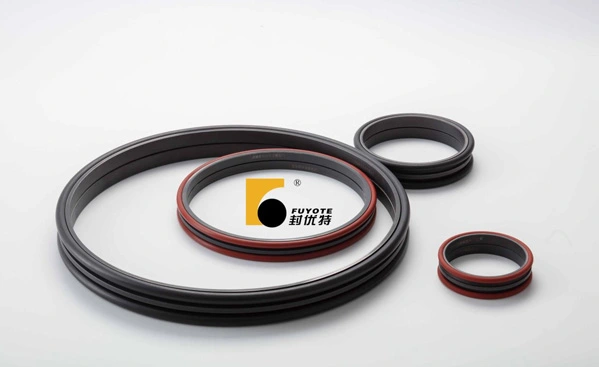

How to choose the floating seal on the tunnel boring machine’s hobbing cutter

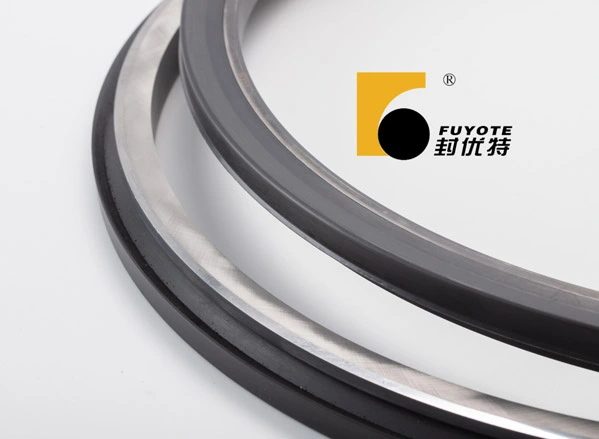

When selecting the floating seal for tunnel boring machine (the floating seal of hobbing cutter), consider the following aspects: metal seal ring material, rubber material, and metal ring manufacturing process. The metal seal ring manufacturing process includes the spherical design of the sealing end face, heat treatment process, and cross oil storage groove design. The choice of o ring needs to be based on the operating temperature and speed, choosing a matching material with good elasticity. These aspects together will determine the service life of the cutter.

More