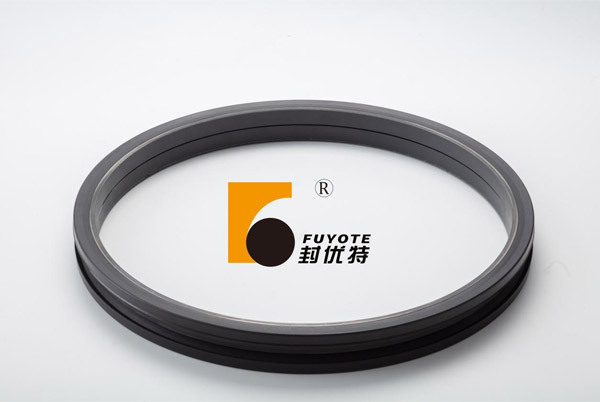

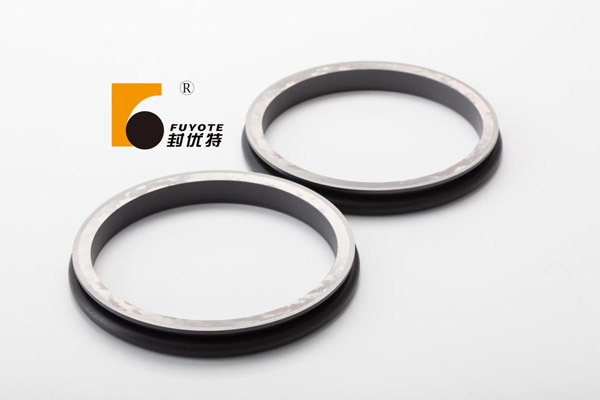

Abstract: Mechanical face seals are crucial components with the capability to float freely, which is vital for their function. They endure considerable forces and friction during machinery operation. Adequate lubrication minimizes friction and wear, reduces energy consumption, and shields the seals from external contaminants. Employing correct oil application techniques is imperative for optimal performance and to prolong the operational lifespan of the seals.

Prior to the lubrication of mechanical face seals, it is imperative to select an appropriate lubricant. The correct choice of lubricant constitutes the fundamental prerequisite for ensuring consistent lubrication across the mechanical face seals. Typically, an ideal lubricant should exhibit excellent lubrication properties, withstand high pressures and temperatures, maintain stability, and resist evaporation or degradation. The selection of a lubricant should be tailored to the specific operational conditions and the usage environment. Attention must be paid to the lubricant’s viscosity and its operational temperature range to guarantee compatibility with the mechanical face seals’ functioning requirements. In selecting a lubricant, one should consult the machinery’s user manual and take into account the mechanical face seal manufacturer’s suggestions.

Before the application of lubricant, it is imperative to ensure that the mechanical face seal’s surface is devoid of any contaminants and residues. All dust and debris must be meticulously removed from the seal’s surface, followed by a thorough cleansing with a cloth. Subsequently, dispense a judicious amount of lubricant and apply it uniformly across the seal’s surface. The lubricant’s volume should be balanced; an insufficiency may lead to inadequate lubrication, whereas an excess could undermine the seal’s integrity. During the lubrication process, gently rotate the mechanical face seal to facilitate an even distribution of the lubricant, thereby enhancing the lubrication efficacy.

To ensure optimal functionality of mechanical face seals, periodic maintenance and inspection are imperative. It’s crucial to meticulously observe the operational state of these seals. Manifestations of abnormal vibrations, excessive noise, or elevated temperatures necessitate immediate diagnostic measures and subsequent remediation.