Abstract: The replaceable floating seal housing addresses the challenge of repairing large components. It is easy to replace, convenient, and cost-effective, thus avoiding wastage of manpower hours. Selecting the appropriate floating seal housing ensures stable equipment operation and reduces maintenance expenses.

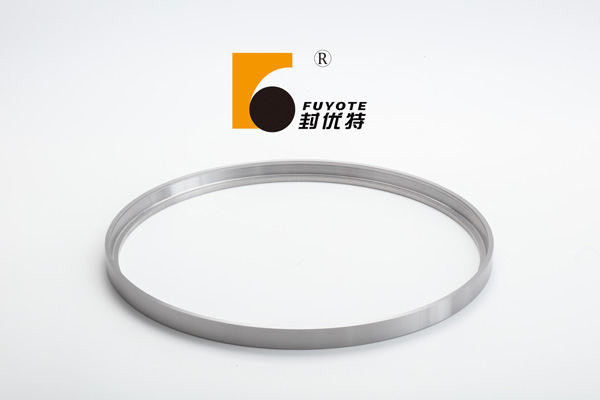

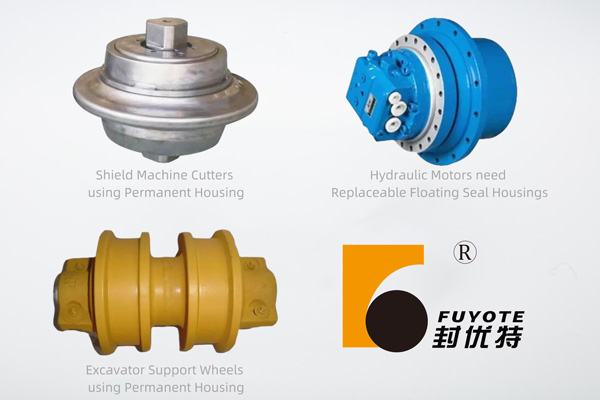

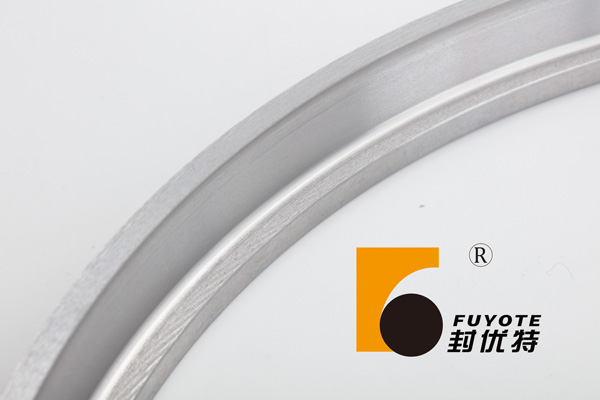

Floating seal housings are available in permanent and replaceable types. For small components such as shield machine cutters and excavator support wheels, permanent housing is recommended. Replaceable floating seal housings feature a small, simple, and easily removable seat placed in the seat cavity. However, replacing the seat on larger components like hydraulic motors can be difficult. Therefore, replaceable floating seal housings are generally preferred. In case of any engineering issues, only the seat needs to be replaced, avoiding significant losses. This also streamlines the processing of the entire component.

The design of replaceable floating seal housings not only enhances maintenance efficiency but also reduces labor waste, especially suitable for situations where large parts require frequent seat cavity replacement. These housings provide convenience for processing the entire part, streamline the maintenance process, and ultimately reduce maintenance costs.

In practical applications, the selection of the appropriate type of floating seal housings is crucial for ensuring the stable operation and maintenance of equipment. For small components requiring long-term stable operation, the use of permanent housing can ensure their sealing and stability. However, for large components that require frequent housing replacement or may experience failures, the design of replaceable housing is more practical. This not only guarantees maintenance efficiency but also reduces maintenance costs, thereby improving the overall reliability and maintainability of the equipment.

In conclusion, the design of replaceable floating seal housings is of significant importance in the field of engineering machinery. It enhances equipment maintenance convenience and efficiency, reduces maintenance costs, minimizes resource waste, and provides strong assurance for the long-term stable operation of the equipment. Therefore, in engineering design and equipment selection, the decision to use replaceable floating seal housings should be based on specific circumstances to achieve optimal maintenance and operational effects.