Mechanical face seals represent a specialized category within the spectrum of oil seal products. Their utilization is crucial in mechanical operations, where external contaminants such as dust and dirt often penetrate the system, leading to irreversible harm. Mechanical Face Seals are thus integral at port interfaces, safeguarding the internal components of machinery.

Mechanical face seals establish a hermetic environment for oil-based machinery, thwarting the escape of lubricants at junctions or ports. This measure forestalls the adverse scenario of machinery running with insufficient lubrication—a condition termed as dry running or dry burning which can precipitate significant damage.

Fuyote’s mechanical face seals play a pivotal role in protecting critical internal components, mitigating wear, and promoting stable operation. This aspect is particularly vital in machinery where replacing parts proves difficult and expensive. High-quality mechanical face seals can significantly diminish the necessity for labor in machine maintenance. In summary, mechanical face seals are of paramount importance for safeguarding mechanical equipment.

Mechanical face seals are ingeniously designed to accommodate a defined range of displacement relative to the shaft. This configuration ensures one component rotates synchronously with the shaft while the other remains static. Such a design adeptly mitigates the impact of minor shaft misalignments, thus preserving the integrity of the seal’s performance in the face of shaft displacement. Furthermore, these seals possess the capability to compensate for the expansion or contraction of parts attributable to thermal variations, consistently maintaining an effective seal.

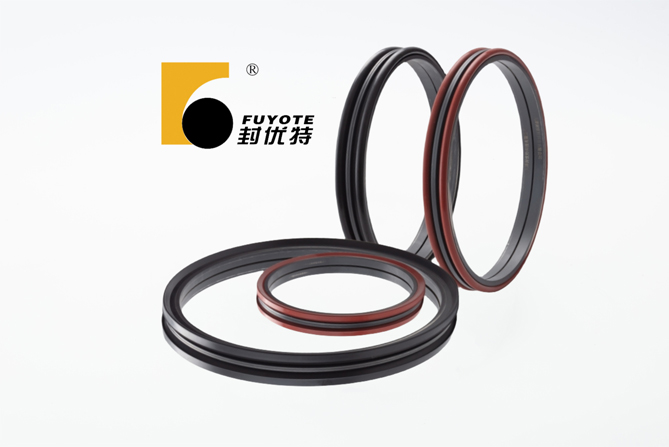

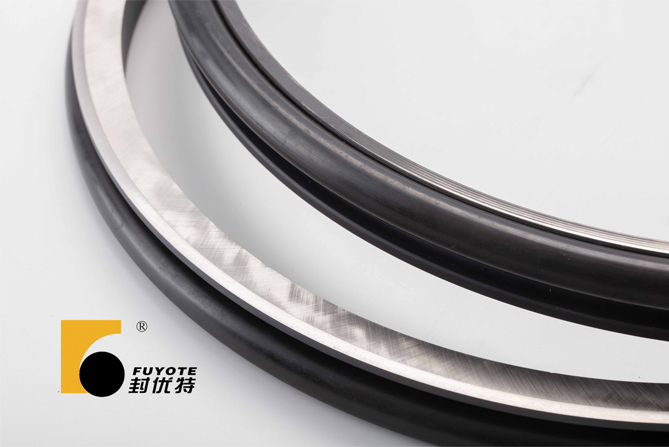

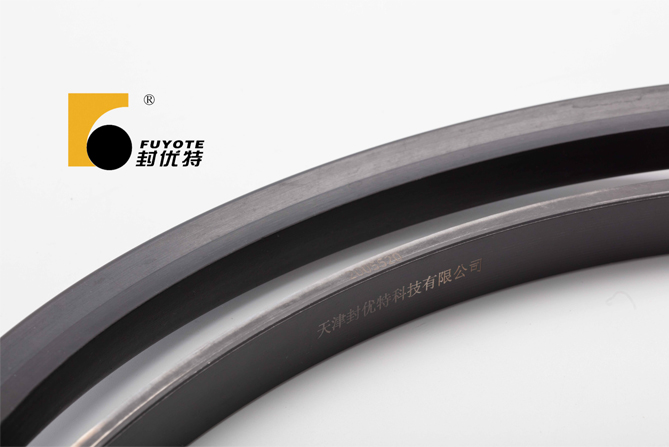

In specialized operational contexts, the adaptability of mechanical face seals is of paramount importance; it contributes significantly to prolonging their operational lifespan and augmenting equipment stability. The selection of materials for these seals is critical. Typically, wear-resistant alloyed cast iron and highly elastic rubber are the preferred materials for Fuyote’s mechanical face seals, ensuring they retain outstanding elasticity and seal integrity, even under complex conditions. Furthermore, the mechanical face seals undergo specialized surface treatments, which often involve processes designed to enhance the bond with rubber rings, thus bolstering their durability and dependability.

Consequently, the adaptability and longevity of mechanical face seals are pivotal in ensuring mechanical integrity. Engineers must evaluate numerous factors when selecting these seals, such as the operational environment, rotational velocity, and ambient temperature, to ascertain that the seals conform to the machinery’s sealing requisites and facilitate the sustained, stable performance of the mechanical system.