Duo cone seal is a common type of sealing device extensively utilized in a variety of construction machinery and mining machinery. It plays a significant role in preventing the leakage of lubricating oil, reducing friction, and wear. When utilizing a duo cone seal, the thickness of the seal oil film is a crucial parameter, which directly affects the sealing performance and the lifespan of the equipment. Therefore, establishing a standard for the thickness of the duo cone seal's oil film is of great importance.

Firstly, the standard for the thickness of the sealing oil film should include both minimum and maximum values. The minimum is set to ensure the stable operation of the sealing oil film, preventing failure of the duo cone seal and damage to the equipment due to an excessively thin oil film. The maximum is established to prevent the oil film from being too thick, leading to seal failure and energy waste.

Secondly, the standard for the thickness of the duo cone seal's sealing oil film should be determined based on factors such as the operating speed, temperature, and properties of the liquid of the equipment. Therefore, it is necessary to establish appropriate testing methods and standards to assess whether the sealing oil film thickness meets the requirements. Through precise measurement and analysis, combined with the conditions of each part, the most suitable range of thickness for the duo cone seal's oil film should be found.

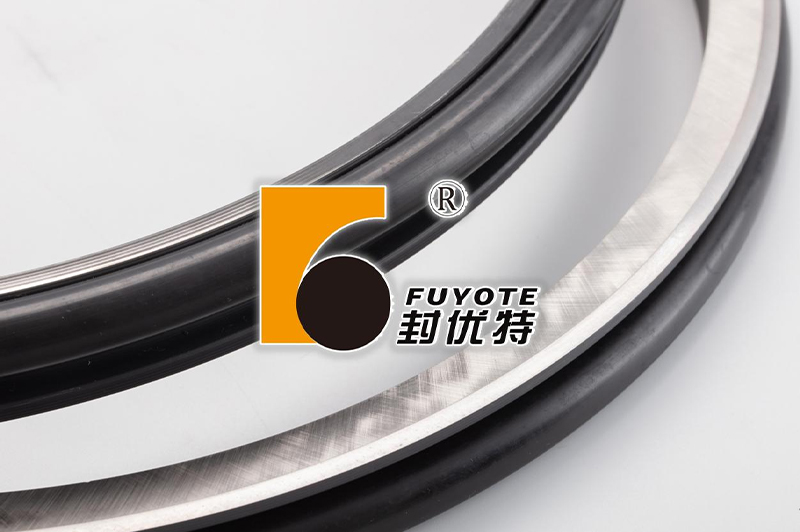

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components manufacturing.