Fuyote’s floating seals play a crucial role in construction machinery. For instance, heavy equipment such as mining excavators and heavy-duty bulldozers utilize floating seals in their hydraulic systems and key components to ensure oil sealing. Given that construction machinery operates under harsh conditions with abundant dust, mud, and high temperatures, the wear resistance and high-temperature tolerance of floating seals become particularly important.

Fuyote’s floating seals play a crucial role in coal mining machinery, such as coal winning machine, underground mining trucks, and the like. Floating seals are also widely used in equipment such as centrifugal pumps and compressors. Within these apparatuses, the principal function of the floating seal is to isolate the internal liquids from the external environment, preventing leaks and contamination. Simultaneously, the sealing efficiency of floating seals can also effectively reduce energy consumption and enhance the efficiency of the equipment.

Additionally, floating seals are widely utilized in equipment across various industries such as metallurgy, mining, petroleum, and chemical engineering. Under conditions of high temperature, high pressure, high velocity, and harsh environments, floating seals can operate stably, safeguarding the normal functioning of equipment and enhancing its reliability.

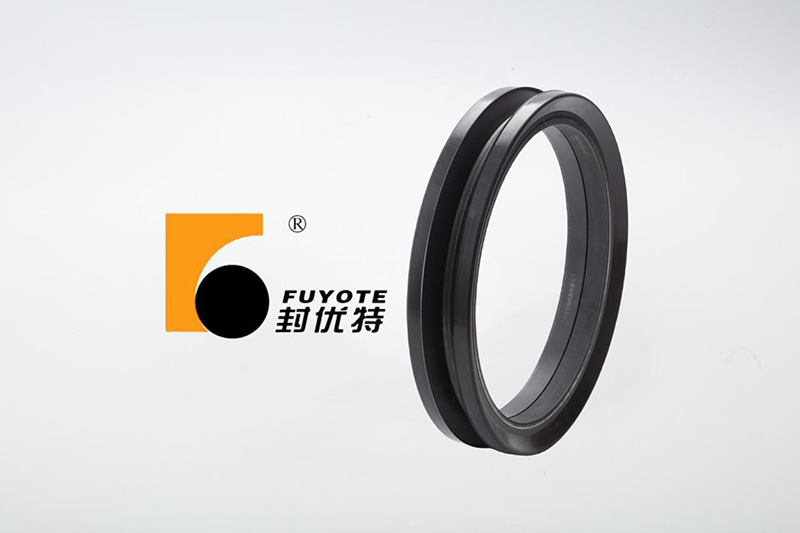

Fuyote established in 1992, has been 30 years in china. Focus on floating seals design and manufacture. In the past two decades, large size floating seals are the main products in fuyote’s production line. Diameter from 300mm to 1105mm are the best-selling products in fuyote. In order to guarantee high quality of the products, Fuyote manufactures all components of mechanical face seals in house, from casting metal rings with high chromium molybdenum to manufacturing elastomer components.