In order to identify high-quality floating seals, the initial step involves recognizing the factors that impact the seals’ quality. In a previous study, we extensively examined how end grinding affects the quality of floating seals. This article will further explore the significant impact of the heat treatment process on floating seal quality.

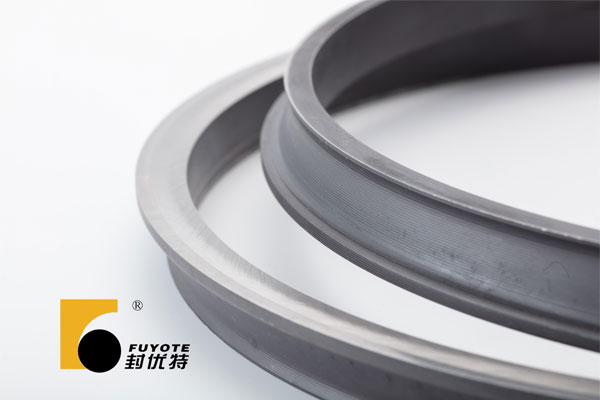

On the left side of the image is a white floating seal (produced without heat treatment during the manufacturing process), and on the right side is a dark gray fuyote’s floating seal (produced with heat treatment during the manufacturing process).

Although both products have anti-slip patterns on the outer wall, the heat-treated dark gray floating seal not only incorporates a “rust prevention” function, but also demonstrates significantly higher coefficients of friction, gripping force on rubber rings, wear resistance, and sealing performance compared to the white floating seal (untreated floating seal). So what is the reason for this discrepancy?

Heat treatment alters the internal structure of materials, imparting unique physical and mechanical properties. The heat treatment process for metals is a multifaceted procedure consisting of three main stages: heating, holding, and cooling. During this process, the movement speed of atoms or molecules within the metal changes, leading to modifications in crystal structure, grain size and distribution, phase composition, and other aspects. These alterations directly influence the mechanical, physical, and chemical properties of metal seal rings.

The effectiveness of the metal seal ring of floating seals is primarily determined by its hardness and organizational structure. Hardness influences the wear and corrosion resistance of the metal seal ring, while the organizational structure impacts its overall stability and durability. Through heat treatment, the internal properties can be effectively adjusted, making the floating seal better suited for sealing requirements. Heat treatment affects the sealing of floating seals in three main aspects.

Grain Refinement: By controlling the temperature and duration of heat treatment, the grains within the metal seal ring of the floating seal can be refined and made more uniform. This improves its hardness, strength, wear resistance, and corrosion resistance, ultimately enhancing its sealing performance.

Stress Elimination: Heat treatment can eliminate the internal stress that occurs during the casting process. This reduces the deformation of the metal seal ring of the floating seal caused by internal stress during operation, thereby maintaining sealing stability.

Formation of Beneficial Surface Layer: Proper heat treatment can result in the formation of a hard and dense oxide film on the surface of the metal seal ring of the floating seal. This further improves its corrosion resistance and wear resistance, extending its service life.

The heat treatment process of the metal ring in floating seals poses a significant challenge for most manufacturers. Particularly in the case of large floating seals with diameters exceeding 500mm-600mm, the heat treatment process of the metal seal ring serves as a key indicator of production technology and product maturity for manufacturers. The distinction between heat-treated and untreated floating seals can be easily identified by color: heat-treated cast molybdenum-chromium alloy iron metal rings exhibit a dark gray appearance, while untreated molybdenum-chromium alloy metal rings appear white. Please note that there may be variations in color for products made of different materials, so the actual situation should be considered.