Floating seals are mechanical seals used to prevent leakage between two parts, like a rotating shaft and housing, in machinery. They are specifically designed for rotary applications in harsh environments, offering resistance to severe wear. These seals effectively prevent the ingress of abrasive and harsh external media, making them ideal for applications where durability and protection from contaminants are critical. Floating seals are also known as metallic seal rings, floating face seals, lifetime seals, toric seals, mechanical face seals, power transmission seals, and metal face seals.

Fuyote, one of the leading floating seal manufacturers in China, provides a high-quality floating sealing system that consists of two separate metal rings and two elastomeric load rings. This system provides positive seal face contact, uniform loading, and dynamic seal-to-shaft alignment and transmits torque to the metal rings in the meantime. As one of the leading floating seal manufacturers and suppliers in the industry, Fuyote offers three types of mechanical face seals: O-ring face seals, heavy duty seals and asymmetric type mechanical face seals. Click the links below and check out the details of our floating seal ring products.

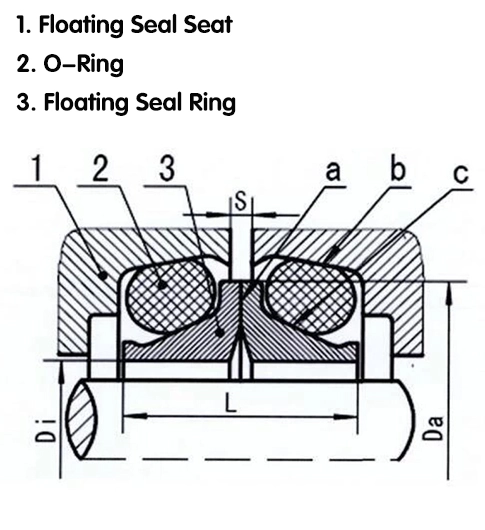

Floating seals consist of two metal friction rings mounted face-to-face in their sealing chambers, with rubber components that apply uniform axial pressure to center the rings. One metal ring remains static while the other rotates, creating friction to maintain the seal. A synthetic rubber O-ring is positioned at the center of the sealing chamber. The sealing chamber and outer ring form two tapered cones, with the taper increasing as depth increases. The surface profile of the sealing chamber is typically machined using CNC tools for precision. This design allows the floating ring seal to accommodate axial and radial movements, ensuring a reliable seal even under shifting or misaligned conditions.

With over 30 years of specialized experience in floating oil seal designing and production, Fuyote, one of the most professional floating seal manufacturers, has an 8000 square meter plant area ensuring large-scale manufacturing capability. Fuyote emphasizes high quality in the floating seal products, catering to both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) requirements.

Fuyote's seal face at 200*magnification, crossed gullies can be observed. Cross hatched grooves on seal contact bands ensure sufficient oil flow and heat management, enabling the seals to operate in the toughest industrial conditions. As the same time it also solve the problem that rubber oil seal cannot solve.

Aim to decrease the difficulties of customer assemble, Fuyote use curve design on sealing face. This design has self-centering to compensate for shaft eccentricity or misalignment under the o-ring pressure, which could increase the sealing stability.

Fuyote use black surface on the metal seal rings. Black seal faces decrease rusting and increase o-ring gripping ability, eliminating o-ring sliding. For customer who require white seal face Fuyote offers anti-skid stripes to achieve the same effect.

As an experienced floating seal supplier, Fuyote provides a range of floating seals, including duo cone seals, heavy-duty seals, floating face seals, floating oil seals, floating ring seals, and more. If you are looking for floating seal suppliers, please don't hesitate to contact us!

Fuyote is a leading floating seal manufacturer, providing high-quality floating seals designed for demanding sealing requirements in harsh environments. These seals ensure durability and reliability in equipment exposed to dust, mud, moisture, and extreme conditions.

Key Applications:

Construction & Mining Equipment: Bulldozers, tunnel boring machines (TBMs), coal cutters

Heavy-Duty Vehicles: Tractors, heavy trucks

Industrial Machinery: Gearboxes, mixers, agitators

Agricultural Equipment: Walking tooth boxes, farming machinery

Fuyote's floating seals deliver superior performance, reducing maintenance and extending equipment lifespan in the toughest working conditions.